Green Energy BU

Process introduction

Release time:2020-02-27 |Author:admin |Reading:164Times

Glue curing

Sealing strips, glue curing equipment, through temperature control to improve the beat of glue curing, thereby improving the automation efficiency of the production line.

Laser welding

It has a variety of process capabilities such as laser flight welding, laser penetration welding, laser brazing, laser wire welding, etc., to achieve the diverse needs of customers for different applications

Glue detection

Automatic visual glue quality inspection

Air tightness test

Fill the workpiece cavity with a certain pressure of gas, and use a proprietary instrument to measure the leakage of the battery box cavity and give the leakage rate.

Cleaning

Automatic cleaning completes oil and welding dust cleaning of parts

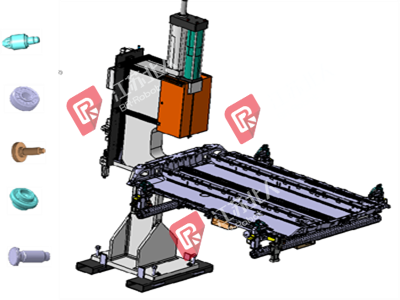

Riveting

Adopt the robot to grab the parts to the fixed riveting station, the device automatically sends nails to automatically complete the riveting operation

Laser mine online detection system

1. Non-contact optical measurement single feature measurement + scanning

2. Simulated three-coordinate mining mode features high measurement accuracy and high efficiency

3. Accuracy 5M range 0.053mm, 2M range 0.024mm

4. High repeatability accuracy 0.03mm, hole 0.05mm full station coverage, measurement reachability 100%

Nut leak detection

Through the visual 3D point cloud system to automatically realize the error-proof and leak detection of parts

上一篇:A battery box glue production line

下一篇:暂无

400-1016-959

400-1016-959 Map

Map